comparison of product paramete

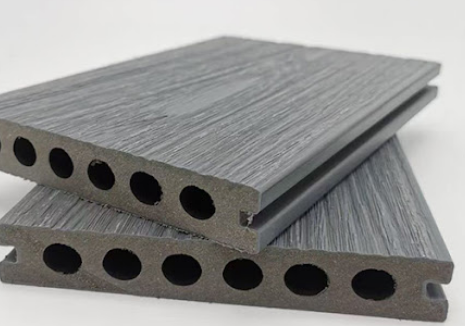

| Product name | Co-Extrusion Round Hole Standard Decking |

| Product number | OHDCRDDWDWCE138023 |

| Product material | Wood powder plastic powder |

| Weight per square meter | 21.03kg |

| Weight per meter | 2.9kg |

| Container Loading (20") | 4872m or 682.08㎡ |

| Section Size (W*T) | 138*23mm |

With economic development and urbanization, people's demand for outdoor landscape architecture is increasing. Outdoor wood-plastic flooring, as an environmentally friendly and durable ground material, has gradually become an important choice for builders. Among them, co-extrusion materials give outdoor wood-plastic flooring more advantages and functions.

As an environmentally friendly, anti-corrosive and durable ground material, outdoor wood-plastic flooring is gradually replacing traditional wooden floors and composite floors in some outdoor landscape and other buildings. Outdoor wood-plastic flooring needs to be exposed to sunlight for a long time, so it must have excellent UV resistance to avoid problems such as color fading and surface aging. have excellent UV resistance and can effectively resist UV radiation and extend the service life of the floor.

Outdoor wood-plastic flooring faces various harsh climatic conditions, such as rain, high temperature, low temperature, etc., and requires high weather resistance of the material. have excellent weather resistance and can maintain stable performance and appearance for a long time in harsh climates. have good chemical resistance and can effectively resist chemical erosion and increase the service life of the floor.

Features of this floor product: 1) evenly and firmly wrapped with a protective layer of polymer material on all sides. The protective layer and the inner layer are extruded at high temperature in one step without using environmentally harmful adhesives. 2) The core material is made of recycled plastic and high-density recycled wood fiber, which is more durable and 100% recyclable. The protective layer uses advanced polymer engineering materials with unique process formula and durability.

The outstanding performance of co-extruded wood is: 1) Resist stains The protective layer has super anti-stain properties and is ultra-low maintenance. Don't worry about stains such as red wine, coffee, soy sauce, vegetable juice, etc. A simple wipe will make your board as bright as new, and the stains will not penetrate into the core layer of the board. 2) Resistant to mildew, rot, cracking, and insect infestation The protective layer provides excellent protection to the board. Fungus and mold cannot grow, crack, or rot, and the board has a longer service life. 3) Anti-fading The protective layer process is unique and the color is more durable than traditional plastic wood. 4) No need for paint The color of the board is part of the production process formula, and there is no need to paint, sand or oil it later, saving worry and effort, and being green and environmentally friendly.

This wood plastic flooring has good chemical stability and is resistant to many different cleaning agents. Its excellent dimensional stability makes it very suitable for long-term outdoor use. It has good weather resistance, and the products produced can still maintain excellent impact resistance after long-term use outdoors.

The company's production base is located in Xifu Town, Chengyang District, Qingdao City. It has a professional R&D technical team and 12 senior engineers. The factory covers an area of more than 40 acres and has an existing factory building of nearly 20,000 square meters.

![]()

Hot Tags: co-extrusion round hole standard decking, China co-extrusion round hole standard decking manufacturers, suppliers, Modern Prefab Commercial Buildings, Lightweight Steel Frame Houses, Modena Pergola, Suspended WPC Ceiling, Core Floor WPC Waterproof Flooring, WPC Panel for Ceiling