Products Description

| Name | WPC Flooring/Decking-Square Hole |

| Material | HDPE+ wood fiber + additives |

| Size | 140mm*25mm |

| Length | Customized |

| Colors | Basic colors/Customized |

| Remark | THE COLOR AND THE SIZE CAN BE CHANGED TO MEET YOUR NEEDS! |

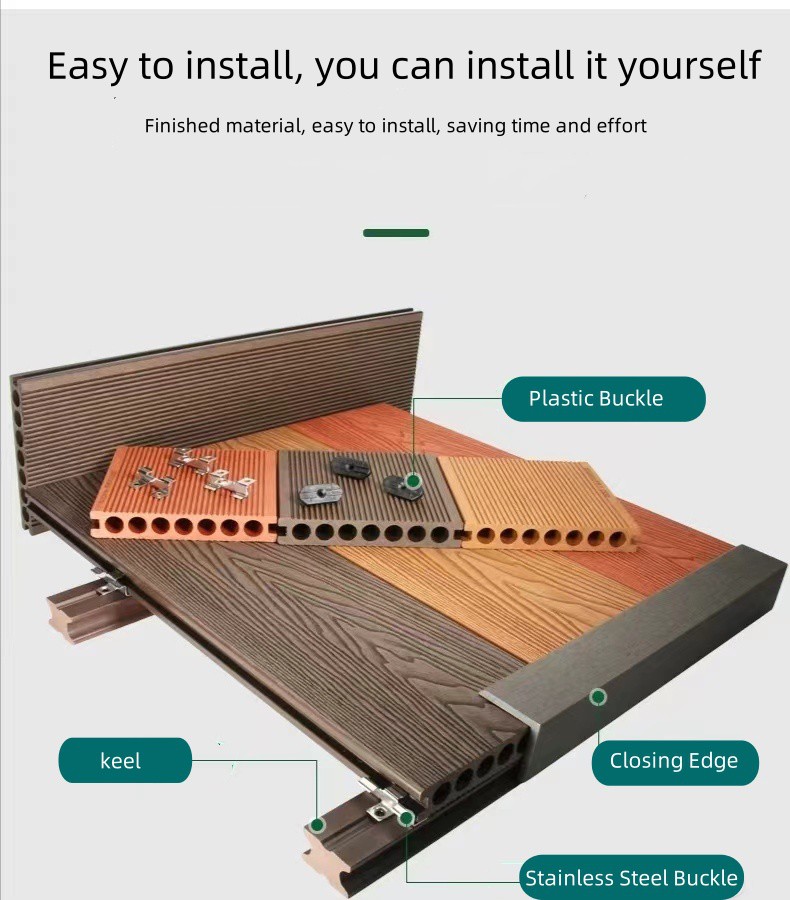

| Accessories | Metal Accessories |

| Package | Fumigated Pallet |

| Application | Garden, Lawn, Balcony, Corridor, Garage, Pool&SPA Surrounds, Boardwalk, Playground |

It manufactured by using extrusion process involving intimate mixing of plastic and cellulose. Wood composite planking that is structured, durable, rot proof, and that has a warm and natural feel to it, with a textured surface just like real wood. The result is a high quantity, long lasting, unnecessary maintenance.

Product advantages

1) High density and strength; Clean, beautiful and colorful.

2) The service life of the floor is about 10 times that of ordinary wood products;

3) Waterproof, fire prevention, resistant to acid and alkali corrosion, insect-resistant, prevent bacteria breeding, can be used outdoor.

4)The capacity to reprocess is excellent and it can be sawed, nailed, drilled, and planed. Non-paint. The size and shape of product can be adjusted.

5)Do not produce secondary pollution; 100% can be recycled and environmentally friendly.

Will never have to paint, stain or seal;

Unnecessary maintenance, non-paint, weatherproof and natural feelingings;

Easy to install -Fire retardant;

Resistant to termites and other wood boring insects;

Water and moisture resistant;

Evironmentally friendly -100%recyclable.

installation steps

1.Drill holes on the concrete ground, put the expansion screws into the holes without exposing.

2.The space between the joist interface and wall head is necessary, the joist should be put in crisscross to avoid the joist interfaces in the same line.

3.Use stainless steel screw to fix the joist, making sure the screw head should be lower than the joist surface, no obvious concavo-convex.

4. Use the screw to fix the first and the last wpc decking board, or, use the screw to fix from the side; or use edged board with clip to fix. Please choose according to your actual requirement.

5 Please drill the holes before fix the screw, the diameter of pre-drilling is no more than 3/4 of screw diameter.

6 After fixing the first board, please use the clip to install in turn.

7. Please use ruler to calculate the width of last board for space reservation in order to cutting properly.

8.Please put the boards cut in turn, push the clip from the last board and the second board from the last, the clip is putted well and please don't fix directly.

9.Drilled and use the screw to fix the last board, pay attention to keep space between decking board and side board.

10. After fixing the last board, then use the screw to fix the clip prepared.

Applications

Packaging and shipping

Hot Tags: waterproof square hole wpc floor, China waterproof square hole wpc floor manufacturers, suppliers, Prefab Commercial Office Building, Lightweight Steel Frame Houses, Outdoor WPC Decking, WPC Wall Panel, WPC Panel for Ceiling, 3D Waterproof WPC Wall Panel