comparison of product paramete

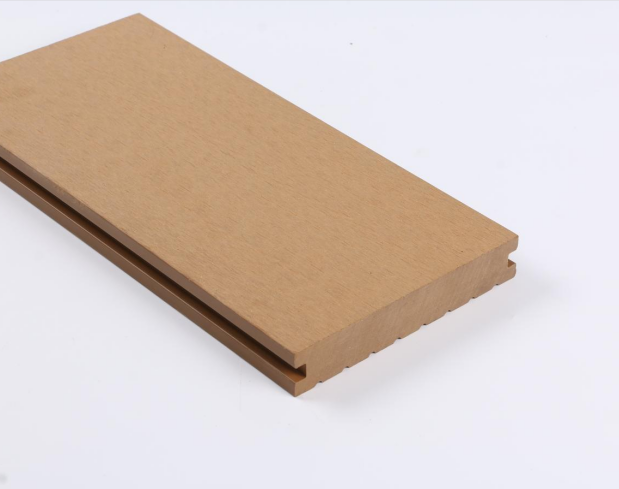

| Product name | Solid Wood Plastic Floor |

| Color | Many Colors Options |

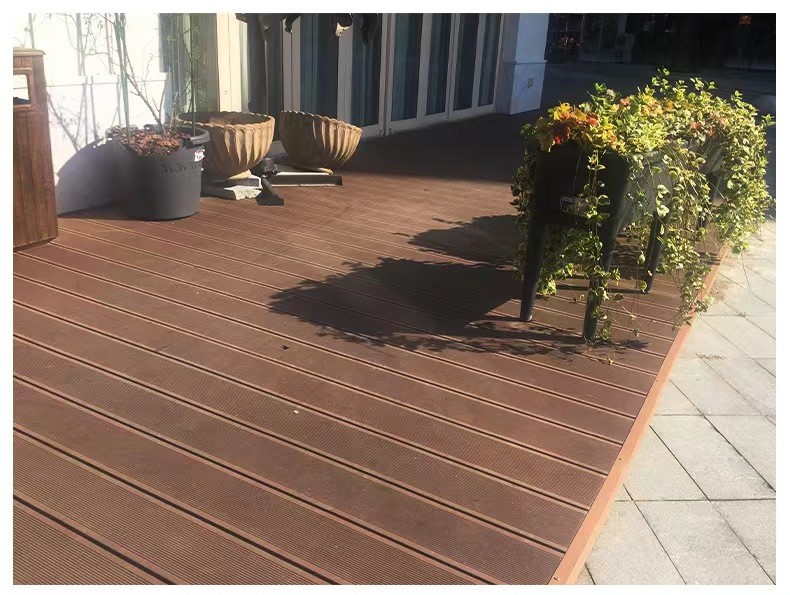

| Usage | Outdoor |

| Material | Wood Powder Plastic Powder |

| Weight per square meter | 31.77kg |

| Weight per meter | 4.45kg |

| Section Size (W*T) | 140*25mm |

| Application |

Patio floors, outdoor seating, park chairs, flower boxes, trellises, pavilions, etc. |

| Installation | Quick&Easy Installation |

Characteristics of solid wood plastic flooring:

1. Looks more like solid wood 2. It has greater load-bearing capacity and is suitable for placing heavy objects on it. 3. Better sound absorption performance

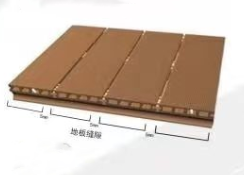

The difference between solid slab and hollow slab:

Exterior:

Both solid boards and hollow boards have a similar appearance to wood and have more color options than wooden boards. As the name suggests, solid boards are made from solid material. Generally solid boards look more realistic, with more variation in grain detail. The most obvious difference in appearance between the two decks is the interior. The interior of the hollow board adopts a hollow tunnel-style design, and square or round holes can be seen in the cross-section. During installation, the exposed cross-section of the hollow board needs to be covered with an edge board.

Function:

Whether it is a hollow board or a solid board, both have better performance than traditional wooden boards. With the development of wood-plastic technology, wood-plastic flooring is more durable than wooden boards and does not require regular painting and maintenance like wooden boards. There are many aspects of performance difference between the two: for example, solid boards generally have better sound absorption performance and are quieter when walking. Solid boards have better strength and load-bearing properties and have a relatively longer service life. Due to the hollow interior design of the hollow board, if water vapor intrudes inside for a long time, the durability will be affected.

Cost:

In terms of materials, since the hollow structure uses less material, the price of hollow wood plastic flooring will generally be cheaper. But from a durability perspective, solid products have better performance and longer service life. Whether you use hollow boards or solid boards, in terms of post-maintenance, you can greatly reduce maintenance costs compared to wooden floors.

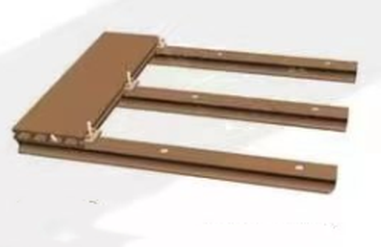

Installation Steps

STEP 1

Before laying, check whether the ground is flat

STEP 2

When installing the first wood plastic floor, use screws to fix the floor directly to the keel to prevent slipping.

STEP 3

Put the buckle into the groove on the side of the floor and fix it on the keel with screws. Be careful not to screw in all the screws. Just fix it a little first.

STEP 4

Lay the next floor, align the slots on the side of the floor with the buckles and insert them, then tighten the screws to fix them on the keels, and so on to install all the subsequent floors.

STEP 5

When installing the last floor, use screws to fix the floor directly on the keel (the fixed position is before the buckle)

STEP 6

Finally, use edge strips to seal the edge of the floor. You can use screws to fix the edge strips directly to the floor.

Hot Tags: solid wood plastic floor, China solid wood plastic floor manufacturers, suppliers, Outdoor WPC Garden Fence, WPC Interior Louvers, Waterproof WPC Outdoor Wall Panel, Residential WPC Louvers, Modern Prefab Commercial Buildings, Outdoor WPC Flooring