The difference between solid and hollow wood plastic flooring

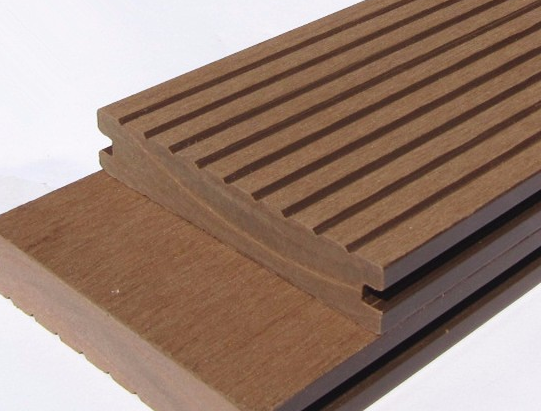

Features of solid wood plastic flooring:

Looks more like solid wood.

With greater load-bearing capacity, it is suitable for placing heavy objects on the deck.

Better sound absorption performance.

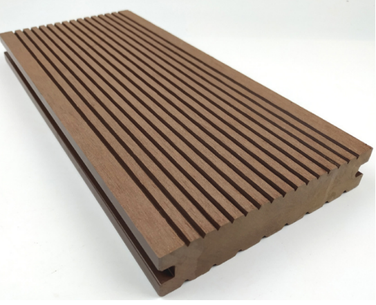

Features of hollow wood plastic flooring:

Light weight, easy to transport and install.

Solid panels are made from one solid piece of plastic composite material with no hollow sections. Sturdy structure and good stability. It is heavier and requires more manpower and time to install. Due to its high density, it has good sound insulation and thermal insulation effects. Usually suitable for flooring in homes and commercial places.

Hollow core panels are made of hollow plastic composite materials with an air layer inside. The structure is lightweight and installation is relatively simple. Light weight, easy to carry and install. The sound insulation and thermal insulation effects are average. It is generally suitable for flooring in homes and commercial places, especially where floors need to be replaced frequently.

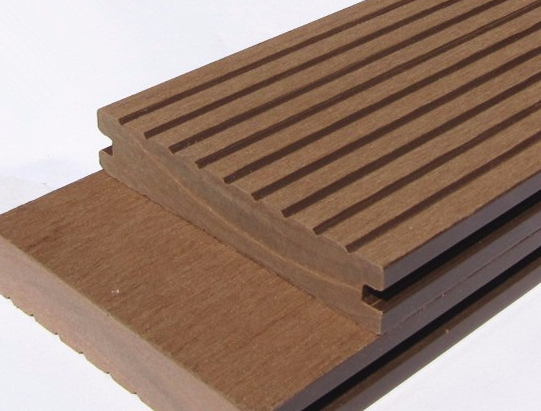

If you need better sound and thermal insulation, as well as a more stable floor structure, you can choose solid panels.

If you are on a budget or need to simplify the installation process, you can opt for hollow core panels.

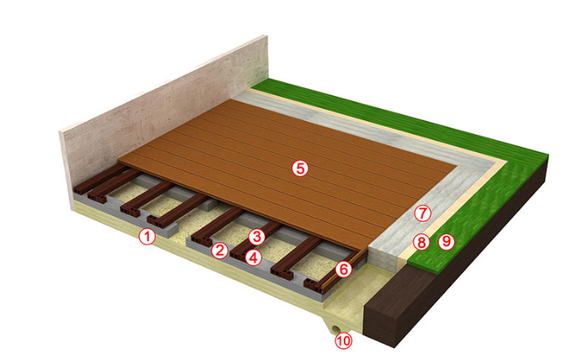

Invisible buckle system:

1.sand layer

2. Concrete slab

3. Substructure frame beams

4. Floor keel

5. Wood plastic flooring

6. Floor starting track

7. Surrounding gravel layer

8. Sand or concrete

9. Turf

10. Drainage

1. Ground inspection: Make sure the floor is flat, dry, clean, and has no obvious unevenness. If the ground is uneven, it needs to be repaired first.

2. Tool preparation: Make sure you have the correct installation tools, such as hammers, saws, measuring tapes, floor glue, floor cutters, etc.

3. Pattern and direction: Before installation, consider the pattern and laying direction of the flooring. It is usually recommended to lay the flooring vertically on the longest wall of the room for better visual effect.

4. Splicing method: When splicing the floors, make sure the connecting grooves and connecting tongues are perfectly aligned, and use a rubber mallet to gently tap the floors to ensure they are tightly connected to the ground. Do not use a metal hammer as it may damage the floor surface.

5. Transition strips and floor edges: Install transition strips at doorways and transitions to ensure a smooth transition between floors. Install floor edges around the edges of the room to protect the edges from damage.

The company focuses on the R&D and design of wood-plastic products and light steel buildings, and is committed to creating the most perfect products to serve every family and the entire society.

The company is located in Qingdao, a beautiful seaside city. The factory covers an area of 20,000 square meters, has 10 wood-plastic production lines, and has an annual output of more than 7,000 tons.

Hot Tags: wood polymer composite flooring, China wood polymer composite flooring manufacturers, suppliers, Prefabricated Modular Container House, Modena Pergola, WPC Wall Cladding Outdoor, Prefabricated Container House, Outdoor Decorative Wall Cladding Panel, WPC Floor Panel