Products Description

| Product Name | Bamboo fiber wall panels |

| Size | 400*7mm,600*8mm,600*9mm |

| Length | 1-4Meters,Customized |

| Material | Bamboo&Wood+PVC+Additives |

| Surface Treatment | Laminated |

| Application | Bathroom,Living room,Ceiling board,TV wall,bedroom,hotel,school,hospital,office,mall |

| Advantage |

1.Modern and custom design 2.Water/Moisture proof 3.Mildew proof 4.Anti-deformation 5.Fire retardant,flame retardant 6.Heat preservation 7.Sound insulation 8.Envionmental protection,free-formaldehyde 9.Easy install |

| Life Time | More than 20 years |

Product advantages

1.Thermal insulation and heat preservation

2.Antibacterial

3.Flame retardant

4.Waterproof and moisture proof.

5. Environmental protection.

6. Fast installation

7.Easy maintenance

8. Various patterns for choosing.

9. Wide range of use 10.Soundproofing.

11.Super anti-skid

12. Wear durability

13.Prevent insect and termite

14.Zero formaldehydeProperties

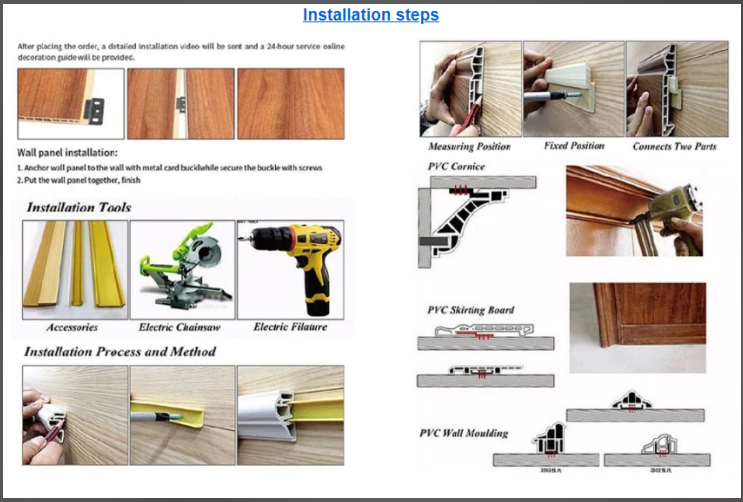

installation steps

1.Preparation:

Make sure the wall or ceiling is flat. If there are uneven areas, they need to be leveled.

Clean the walls to make sure they are free of dust and debris.

2.Install keel:

Measure and mark where the keel will be installed. Generally speaking, the keel spacing is 30-40 cm.

Use an electric drill or hammer to secure the wooden strips or aluminum joists to the wall or ceiling. Make sure the keel is securely installed and level.

3.Cut Bamboo Fiber Board:

Use a tape measure to measure and mark the cut lines of the bamboo fiberboard according to the desired size.

Use an angle grinder or saw to cut the bamboo fiberboard to the desired size.

4.fixed bamboo fibreboard:

Starting from a corner, place the first piece of bamboo fiber board on the keel and secure it with screws or nails. Fixing points should be at the edges and middle part of the board.

Leave a gap of about 2-3 mm between each board to prevent thermal expansion and contraction.

Then install the next board, ensuring a tight fit between the boards, and continue to secure it with screws or nails.

5.Treat corners and seams:

After all the bamboo fiber boards are installed, use sealant to seal the joints between the boards and the gaps between the boards and the edges of the wall or ceiling.

If there are corners, they need to be cut and adjusted according to the actual situation.

6.Surface treatment:

If necessary, a layer of protective paint or decorative paint can be applied to the surface of the bamboo fiber board to increase its beauty and durability.

Applications

(1) Household ornament: Wall and ceiling of indent independent house bathroom or kitchen.

(2) Public and management place: Toilet of building and hall.

(3) Common office: Ceiling of business place.

(4) Hotel, business office, hospital, school, cooking room, washing room and etc. indoor decoration.

Packaging and shipping

A: What are the characteristics of PVC foam board materials?

1. Lightweight: PVC foam board is a lightweight material that is convenient for handling and installation.

2. Good impact resistance: PVC foam board has high impact resistance and can absorb external impacts to a certain extent.

3. Good weather resistance: PVC foam board can effectively resist the influence of external envirnments such as UV, moisture, and high temperature.

4. Chemical resistance: PVC foam board has good chemical resistance and can resist the erosion of some chemical substances.

5. Sound insulation and insulation: PVC foam board has certain sound insulation and insulation effects, which can provide a more comfortable environment.

B: What application areas are PVC foam boards commonly used in?

1. Architecture and decoration: used for interior and exterior wall finishes, ceilings, partitions, etc.

2. Advertising and Exhibition: Used for the production of billboards, signage, exhibition boards, and POP advertisements.

3. Vehicle manufacturing: used for body interior panels, carriage panels, and workshop panels.

4. Car display: Used for the construction of car exhibitions and displays.

5. Industry and packaging: used for manufacturing models, mold plates, and packaging boxes.

Hot Tags: bamboo fiber wall panels, China bamboo fiber wall panels manufacturers, suppliers, Prefab Cargo Container Homes, WPC Louvers, Prefabricated Container Building, Prefab Steel Commercial Buildings, Prefabricated Modular Container House, 3D WPC Decorative Wall Panels