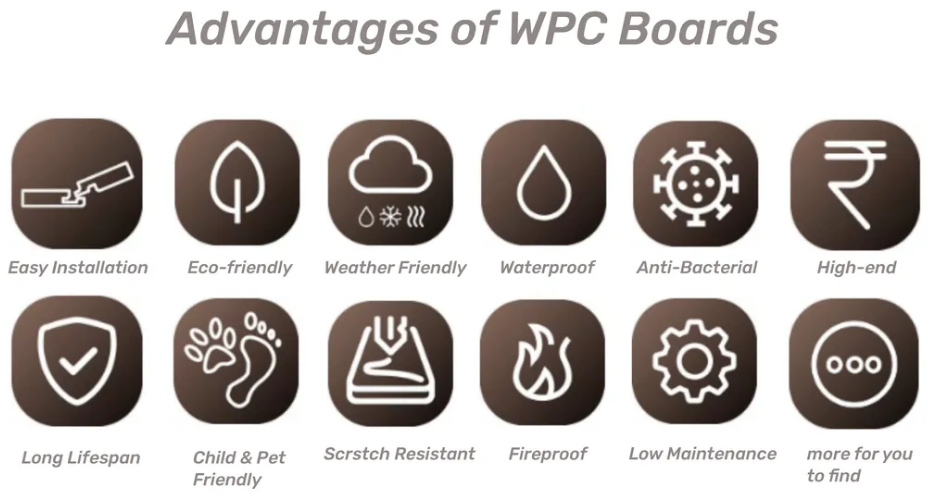

Composition of raw materials for outdoor wood plastic Great Wall panels:

60% of wood fiber

Mainly use Poplar powder.

Compared with mineral fibers, wood fiber raw materials have a wide range of features, low price,can be reprocessed, can be naturally regenerated, biodegradable, low density and so on.

In addition, wood fibers are used as an enhanced material in thermoplastics and show better mechanical properties, such as low hardness, low wear on processing equipment.

30% of plastic

We use HDPE. The choice of plastic mainly from its own performance, product requirements, supply situation and cost.

Due to the thermal stability of wood fibers, only thermoplastics with melting points below 200 ºC are usually used in WPC production

Commonly used plastics are recycled polyethylene(PE), polypropylene(PP), polyvinyl chloride(PCV) etc.

Among them, PE has always been the most important plastic raw material in wood plastic production.

10% additives

Added to the formulation of plastics and other composites to improve its sun resistance and prevent or reduce the damage caused to

plastics by UV rays in sunlight, collectively known as photostabilizers.

Antioxidants can slow or inhibit plastic oxidation degradation

Lubricants can reduce friction and change the processing performance during the molding process of wood-plastic composite materials

Colorants, antistatic agents, anti-mold and preservatives are also added to the formula.

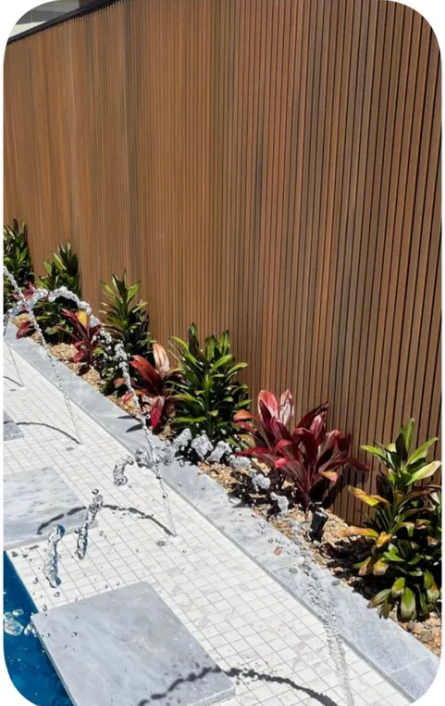

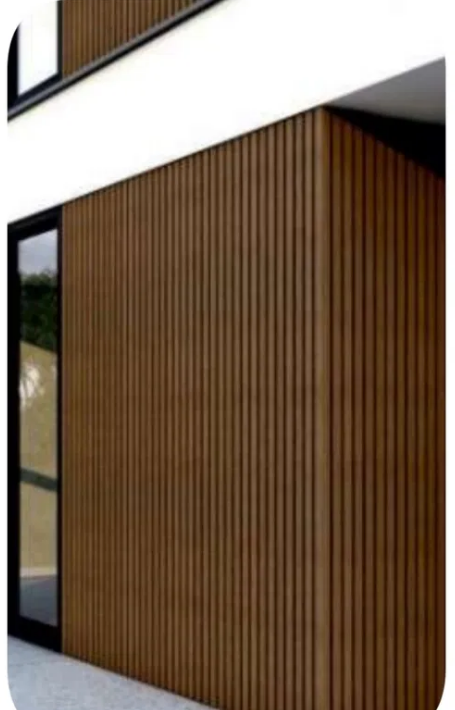

Case Presentation:

Hot Tags: hot selling outdoor wpc great wall panels, China hot selling outdoor wpc great wall panels manufacturers, suppliers, Waterproof WPC Fence, Prefab Steel Container Homes, Pergola, Modena Pergola, Outdoor WPC Flooring, WPC Outdoor Fence