1. Material differences:

Heavy steel house materials: Heavy steel houses usually use traditional carbon structural steel. These steels have larger thicknesses and cross-sectional sizes, including H-shaped steel, I-shaped steel, channel steel, angle steel, etc. These steels have high yield and tensile strengths and can withstand greater loads and pressures. Heavy steel buildings are made of materials with high density and strength, and are suitable for large buildings that require high load-bearing capacity and structural stability, such as industrial plants, high-rise buildings and large public facilities.Heavy steel house materials: Heavy steel houses usually use traditional carbon structural steel. These steels have larger thicknesses and cross-sectional sizes, including H-shaped steel, I-shaped steel, channel steel, angle steel, etc. These steels have high yield and tensile strengths and can withstand greater loads and pressures. Heavy steel buildings are made of materials with high density and strength, and are suitable for large buildings that require high load-bearing capacity and structural stability, such as industrial plants, high-rise buildings and large public facilities.

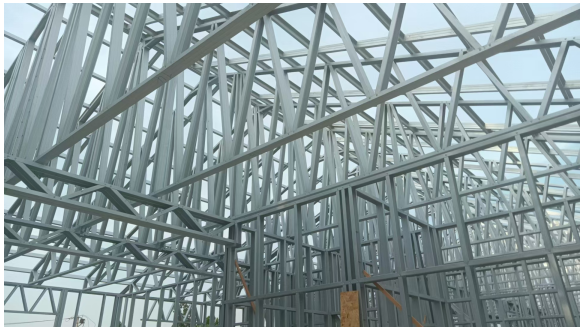

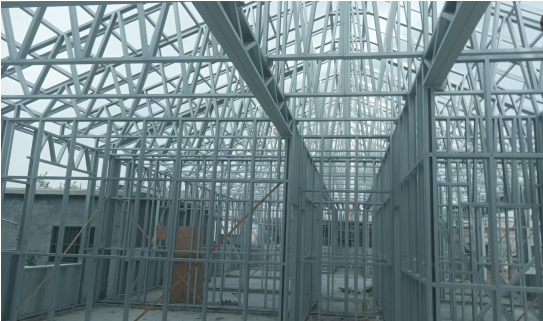

Light steel house materials: Light steel houses mainly use lightweight steel, such as cold-formed thin-walled steel (C-shaped steel, Z-shaped steel, etc.) and galvanized steel plates. These steels are characterized by being thin-walled and lightweight, yet still retaining sufficient strength and stiffness. The galvanizing treatment of light steel houses improves the corrosion resistance of the material and extends the service life of the material. Light steel houses have low material density and moderate strength, and are suitable for small buildings, temporary buildings, mobile homes and low-rise residences.Light steel house materials: Light steel houses mainly use lightweight steel, such as cold-formed thin-walled steel (C-shaped steel, Z-shaped steel, etc.) and galvanized steel plates. These steels are characterized by being thin-walled and lightweight, yet still retaining sufficient strength and stiffness. The galvanizing treatment of light steel houses improves the corrosion resistance of the material and extends the service life of the material. Light steel houses have low material density and moderate strength, and are suitable for small buildings, temporary buildings, mobile homes and low-rise residences.

2. Structural differences:

Structural form: Heavy steel houses usually adopt frame structure or frame-braced structure, which can provide higher load-bearing capacity and better seismic performance. Frame structures bear vertical and horizontal loads through a frame formed by steel beams and columns, while frame-braced structures add diagonal bracing to improve overall stability.Structural form: Heavy steel houses usually adopt frame structure or frame-braced structure, which can provide higher load-bearing capacity and better seismic performance. Frame structures bear vertical and horizontal loads through a frame formed by steel beams and columns, while frame-braced structures add diagonal bracing to improve overall stability.

Light steel houses mostly use light steel keel structures. This structural form is relatively simple and mainly consists of light steel keels and cladding materials. Light steel keels serve as the skeleton, and cladding materials (such as color steel plates, fiberglass plates, etc.) serve as the covering layers of walls and roofs. This structure is light in weight and fast in construction, but has relatively low load-bearing capacity and stability.Light steel houses mostly use light steel keel structures. This structural form is relatively simple and mainly consists of light steel keels and cladding materials. Light steel keels serve as the skeleton, and cladding materials (such as color steel plates, fiberglass plates, etc.) serve as the covering layers of walls and roofs. This structure is light in weight and fast in construction, but has relatively low load-bearing capacity and stability.

3. The difference between good and bad:

The advantage of heavy steel houses lies in their high load-bearing capacity, stability and safety, making them suitable for long-term and important buildings. However, its cost is high, the construction period is long, and it is not easy to dismantle and relocate.The advantage of heavy steel houses lies in their high load-bearing capacity, stability and safety, making them suitable for long-term and important buildings. However, its cost is high, the construction period is long, and it is not easy to dismantle and relocate.

Light steel houses are cost-effective, fast to construct, easy to dismantle and relocate, and are suitable for buildings with limited budgets and rapid construction requirements. However, its carrying capacity is relatively low, its stability and safety are poor, and its service life is relatively short.Light steel houses are cost-effective, fast to construct, easy to dismantle and relocate, and are suitable for buildings with limited budgets and rapid construction requirements. However, its carrying capacity is relatively low, its stability and safety are poor, and its service life is relatively short.

4. Differences in material selection:

Heavy steel buildings usually use larger specifications of steel, such as H-shaped steel, I-shaped steel, channel steel, angle steel, etc. These steel materials have larger thickness and cross-sectional size, which can provide higher strength and stiffness. In terms of materials, heavy steel houses mostly use carbon structural steel, which has high yield strength and tensile strength.Heavy steel buildings usually use larger specifications of steel, such as H-shaped steel, I-shaped steel, channel steel, angle steel, etc. These steel materials have larger thickness and cross-sectional size, which can provide higher strength and stiffness. In terms of materials, heavy steel houses mostly use carbon structural steel, which has high yield strength and tensile strength.

Light steel houses mostly use thin-walled light steel, such as cold-formed thin-walled steel (C-shaped steel, Z-shaped steel, etc.) and galvanized steel plates. These steels are characterized by being thin-walled and lightweight, yet still retaining sufficient strength and stiffness. Material-wise, light steel houses may use low-alloy steel or high-strength steel to reduce weight while maintaining structural performance.Light steel houses mostly use thin-walled light steel, such as cold-formed thin-walled steel (C-shaped steel, Z-shaped steel, etc.) and galvanized steel plates. These steels are characterized by being thin-walled and lightweight, yet still retaining sufficient strength and stiffness. Material-wise, light steel houses may use low-alloy steel or high-strength steel to reduce weight while maintaining structural performance.

5. Price difference:

6. Main structure:

There are obvious differences in the main material structure between light steel villas and heavy steel villas, which are mainly reflected in the specifications, models and thickness of the steel. These differences directly affect the load-bearing capacity, stability and durability of the villa.There are obvious differences in the main material structure between light steel villas and heavy steel villas, which are mainly reflected in the specifications, models and thickness of the steel. These differences directly affect the load-bearing capacity, stability and durability of the villa.

7. Anti-corrosion process:

Light steel houses are usually connected using self-tapping screws. Self-tapping screws can be screwed directly into the steel without pre-drilling, which maintains the integrity of the zinc film and thus improves corrosion resistance. Zinc film is a protective film on the surface of light steel materials, which can prevent the steel from being directly exposed to the air and reduce the risk of oxidation and corrosion. In addition, the installation process of self-tapping screws is simple and fast, which helps to improve construction efficiency and reduce labor and time costs.Light steel houses are usually connected using self-tapping screws. Self-tapping screws can be screwed directly into the steel without pre-drilling, which maintains the integrity of the zinc film and thus improves corrosion resistance. Zinc film is a protective film on the surface of light steel materials, which can prevent the steel from being directly exposed to the air and reduce the risk of oxidation and corrosion. In addition, the installation process of self-tapping screws is simple and fast, which helps to improve construction efficiency and reduce labor and time costs.

Chongqing Steel Houses are assembled using national standard high-strength carbon steel nuts. This type of connection does not require welding, but uses bolts and nuts to join the steel together. The national standard high-strength carbon steel nut has high strength and stability, which can ensure the firmness and safety of the connection. After installation is completed, the connection parts of the heavy steel house will be coated with an anti-rust film to further enhance its corrosion resistance. Although the construction process is complicated, this connection method provides higher structural stability and durability, and is suitable for buildings that require high load-bearing capacity and long-term stability.

8. Security:

The light steel villa uses Dacromet screws for fixed connections, and the foundation and main body have strong wind resistance. As for heavy steel villas, the main body is connected by main embedded parts, which can usually withstand earthquakes of magnitude 9 or above.

9. Thermal insulation:

Insulation cotton is usually installed in the walls of light steel villas. This kind of thermal insulation material has good thermal insulation effect, can effectively reduce the exchange of indoor and outdoor heat, and maintain the stability of indoor temperature. In cold areas, thermal insulation cotton can prevent the loss of indoor heat, while in hot areas, it can prevent the entry of external heat, thereby achieving the purpose of energy saving and consumption reduction. In addition, thermal insulation cotton also has good sound insulation properties, which can improve living comfort.

Chonggang villas use a more complex thermal insulation system. Exterior walls usually use composite wall panels, which not only have excellent waterproof and fireproof properties, but also have good thermal insulation effects. Composite wall panels are composed of multiple layers of materials, including insulation layers, structural layers and decorative layers, which can effectively isolate indoor and outdoor heat transfer. There will also be a specially designed thermal insulation layer on the top of the floor, which not only improves the thermal insulation performance of the villa, but also has the effect of keeping the villa warm in winter and cool in summer, making the living environment more comfortable and energy-saving.

10. Carrying capacity:

The load-bearing capacity of light steel villas is relatively low and can only bear about 350 kilograms per square meter. This means more support structures are needed to ensure the stability of the house during design and construction. Due to the small span, a support is usually required every 60 centimeters. This design limits the internal space layout and flexibility of the house. In addition, the maximum span of light steel villas generally does not exceed 6 meters, which further limits the design options of the house. In later use, when installing heavy equipment such as water heaters and air conditioners, it is necessary to plan and bury corresponding components in advance to ensure the safe installation and use of the equipment.

Heavy steel villas use national standard H-shaped steel buildings, whose stress capacity reaches 850 kilograms per square meter, which is significantly higher than light steel villas. This structural design allows heavy steel villas to withstand greater loads, provide larger spans and more flexible internal space layout. The span of heavy steel villas can reach 10 meters, providing more design possibilities and usage space for the house. In terms of floor design, Chonggang Villa not only lays steel base plates to improve stability, but also pours a cement layer with a thickness of 10 cm. This structure is not only thick and stable, but also provides higher load-bearing capacity and durability.

11. Construction efficiency:

The construction efficiency of light steel villas is usually higher. Because the materials used in light steel villas are small in size and thin in thickness, they are lighter and easier to transport and install. In addition, light steel villas have a high degree of prefabrication, and most components can be prefabricated in the factory and then transported to the construction site for rapid assembly. This prefabricated construction method can significantly shorten the construction cycle and reduce the need for on-site construction personnel, thus reducing the cost of manpower and time. The construction process of light steel villas is relatively simple and does not require large-scale construction equipment. It is easier to adapt to various construction environments and improve construction efficiency.

The construction efficiency of heavy steel villas is relatively low. Because the materials used in heavy steel villas are large in size and thickness, they are heavier and require large construction equipment and a professional construction team to install. The construction process of Chongqing Steel Villa is relatively complex and requires precise measurement, cutting, welding and hoisting. In addition, the construction period of Chonggang villas is longer, requiring more time and labor costs. However, heavy steel villas have high structural strength and good seismic resistance, and are suitable for large industrial buildings, high-rise buildings, etc. The demand in these markets is relatively stable, but competition is fierce and price wars may lead to compression of profit margins.

12. Exterior wall decoration (appearance):

The exterior wall decoration of light steel villas usually uses lightweight and easy-to-construct materials. Common decorative materials include color steel panels, fiber cement panels, aluminum-plastic panels, etc. These materials are lightweight, easy to install, come in a variety of colors and are low cost. Color steel plate is a commonly used exterior wall decoration material. It is made of galvanized steel plate coated with multiple layers of paint and has good weather resistance and corrosion resistance. Fiber cement panels provide a look and feel closer to traditional building materials. These materials can be selected according to personal preferences and design requirements to achieve different appearance effects.

The exterior wall decoration of Chonggang villas pays more attention to durability and functionality. Common decorative materials include stone, glass curtain walls, metal panels, etc. Stone offers a high-end, classic look, but is more expensive and complex to construct. The glass curtain wall provides a modern, transparent appearance and has good thermal insulation performance. Metal panels, such as aluminum or stainless steel, provide a smooth, easy-to-maintain look. The use of these materials not only improves the appearance of the building, but also enhances the stability and durability of the building.

13. Service life:

The service life of light steel villas is usually short, generally 20-30 years. This is because the thickness of the steel used in light steel villas is thin. Although it has been treated with anti-corrosion, problems such as corrosion, fatigue and deformation may still occur during long-term use. In addition, the connection methods of light steel villas (such as self-tapping screw connections) may become loose or damaged over time, requiring regular maintenance and replacement. Therefore, light steel villas may require more maintenance and replacement work during use to ensure the safety and stability of their structures.

The service life of heavy steel villas is relatively long, generally reaching more than 50 years. This is because the steel used in heavy steel villas is thicker, has higher strength and stiffness, and can withstand greater loads and pressures. In addition, Chongqing Steel Villas will undergo strict anti-corrosion treatments during the construction process, such as hot-dip galvanizing, painting, etc. These treatments enhance the corrosion resistance of the building and extend the service life of the materials. The connection method of heavy steel villas (such as national standard high-strength carbon steel nut assembly) is stronger, reducing the risk of loosening and damage. Therefore, heavy steel villas have higher stability and safety during use, reducing the frequency of maintenance and replacement.