Carbon crystal board construction process and application scenarios

The construction process of carbon crystal board is simple, and the construction process is mainly reflected in the joints between boards and how to close the corners.

1. Closing method

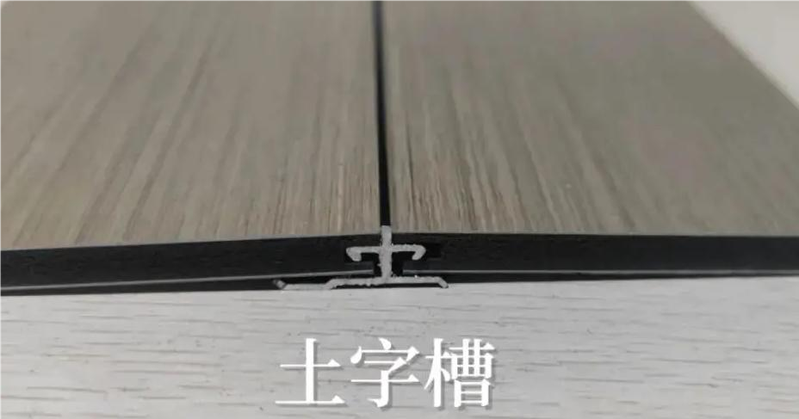

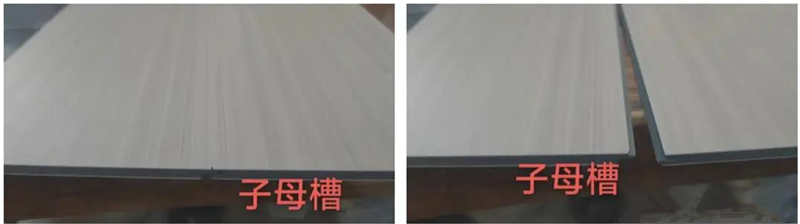

1) The joints between large boards are made by grooving on the back, which can be in the form of earth-shaped grooves, mother-and-child grooves, and combined metal profiles.

2) The corners are treated by profile closing strips, arc bending, right-angle bending, etc.

2. Construction process flow:

1) Wall treatment

The wall is leveled with wood boards or wooden strips (keels), and wooden strips (keels) are used for leveling. Note that the distance between wooden strips should not be too large.

2) Install carbon crystal board

Structural glue is applied on the back of the carbon crystal board. The glue application method is to apply glue horizontally and vertically around the board, and the glue thickness is about 1CM.

3) Wall treatment

The board edge should be parallel to the horizontal line when tested with a level. If not, move the board to adjust the parallelism and evenly tap the carbon crystal board with a rubber hammer to make the board close to the wall.

4) Embed metal I-shaped strips

After the first board is fixed, embed the metal I-shaped strips on the side of the board and fix it with F25 straight nails, and then install the second board in sequence. If the carbon crystal board has been opened with mother-and-child grooves in advance, it can be spliced directly without the need for metal strips to close the ends.

3. Application scenarios of carbon crystal boards

Application in home space

Application in commercial space

Hot Tags: carbon crystal plate is the first choice for decoration, China carbon crystal plate is the first choice for decoration manufacturers, suppliers, Solid WPC Floor, WPC Interior Louvers, Outdoor Waterproof WPC Wall Clad, WPC Wall Panel, Modern Prefab Commercial Buildings, New Design WPC Ceiling Panel