Why choose us?

factory Outlet

We support on-site factory inspections, high-efficiency automated production equipment, and annual sales of 7,000+ tons

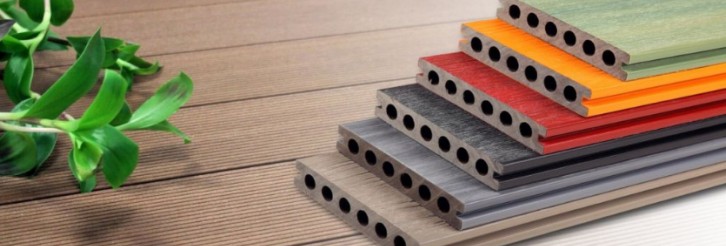

Various specifications

There are a variety of specifications to choose from, and you can get free samples (customized samples are not free) to meet the market's requirements for outdoor flooring.

Worry-free quality

Each raw material is selected, and the material meets environmental protection requirements, has no odor, is healthy and environmentally friendly, and guarantees quality and quantity.

![]()

Support customization

We have a wide variety of products and support customer customization. Customers must inform us of their needs in advance for customization.

![]()

1.Use of outdoor flooring park wetlands

Accompanying the development of ruralization, economic progress. Urbanization continues to advance, more and more Gaokou mansions are built, and large numbers of people migrate to cities and towns. At this time, some surrounding wetland parks are needed to improve the living atmosphere and environment. As a rural ecological regulation and leisure space, the surrounding wetland park scenic areas play an important role in urban development and climate regulation. However, during the construction of park wetland scenic spots, in order to achieve a more ideal ecological leisure effect, a large number of solid wood products or anti-corrosion wood are often used as landscape plank flooring, which wastes forest wood resources, has a short service life, and causes damage to the environment. At this time, we need to find a more environmentally friendly wood - plastic wood. The appearance and wood texture are realistic and natural, the data stability is good, and it has the dual advantages of wood and plastic in terms of performance. Not easy to crack, deform, or warp. Anti-aging, corrosion-resistant, insect-proof and low water absorption. It comes in rich colors and is as easy to work with as wood, cutting, planing, nailing and drilling are all simple. In addition, wood-plastic flooring is produced using high-temperature melting and high-pressure extrusion; therefore, the structure of wood-plastic flooring products is denser. The density of wood plastic flooring is about 3 times that of conventional wood at 1.3g/cm3. Therefore, wood-plastic flooring has better anti-mildew, anti-corrosion, moisture-proof, and insect-proof effects than anti-corrosion wood. It also has better wear resistance, stain resistance, and better aging resistance.

2.Applications

Composite of wood fiber and plastic, it has the advantages of water resistance, corrosion resistance, wear resistance, etc., so it has a wide range of applications indoors and outdoors. Terraces and balconies, garden paths, seaside paths, sidewalks, shop floors, courtyard floors, etc.

3.Precautions for installation process

When installing plastic wood flooring, we need to use some tools and materials, such as floor glue, floor hammer, floor cutter, etc. When using these tools and materials, we need to pay attention to safety and avoid accidental injuries. In order to ensure the quality of floor installation, you also need to be familiar with the process of floor installation, such as the laying direction of the floor and the treatment method of joints. If you are not familiar with the installation process, it is recommended to ask professionals or installers with certain experience to perform the construction.

![]()

Application scenarios

Hot Tags: plastic wood effect flooring, China plastic wood effect flooring manufacturers, suppliers, Decorative WPC Wall Panel, White Louvered Pergola, Corridor WPC Ceiling Panel, 3D Waterproof WPC Wall Panel, Co extrusion WPC Wall Panel, Circular Pergola with Roof