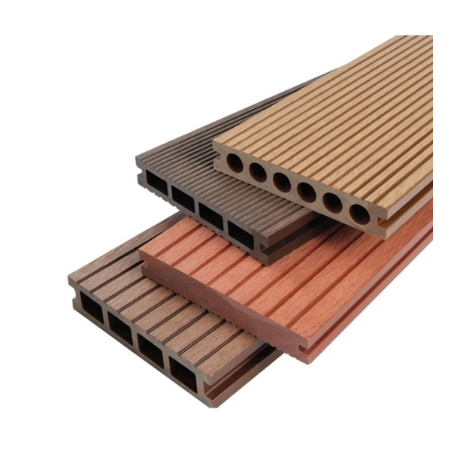

| Product Name | Wood Plastic Composite Hollow Decking |

| Application | Outdoor Construction |

| Usage | Household, Outdoor, Commercial |

| Surface | Groove,Sanding,Wood Grain |

| Component | 30%PE+60% Wood Fibers+10%Additives |

| Size | 140*25mm |

| Advantage | Eco-Friendly Weather Resistant |

| Color |

Customized according to customer needs |

| Length | 2.2m,2.9m customizable |

Main Feature

1) Waterproof, mildew-proof, corrosion-proof, super durable.

2) High recyclability, environmental protection, and saving forest resources.

3) Has the look of natural wood, but with fewer wood problems.

4) No paint, no glue, low maintenance cost.

5) There are many colors to choose from.

6) Easy to install and clean.

Advantage:Waterproof,Fireproof,Moisture-proof, anti-corrosion, anti-insect, Long service life.

Intimate design, just for you

Products Details

Waterproof and moisture-proof

Good product stability, high gloss and high fluidity.

texture texture

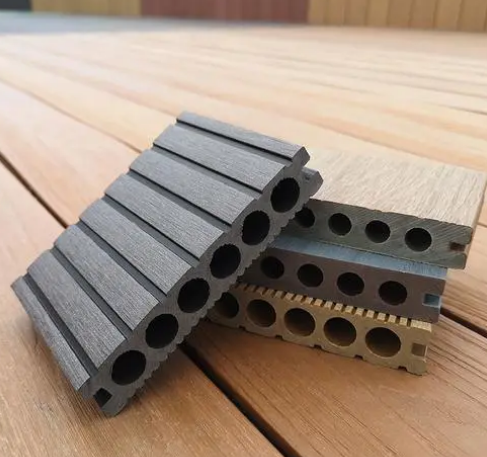

The texture is rich in layers and visually full, and the concave-convex process restores the texture of solid wood.

Wood plastic substrate

Polymer protective layer, good pressure and wear resistance.

Application Scenarios

Outdoor venues: such as courtyards, balconies, terraces, around swimming pools, etc.

Public places: such as park trails, squares, piers, etc.

Architectural decoration: such as wall decoration, guardrails, fences, etc.

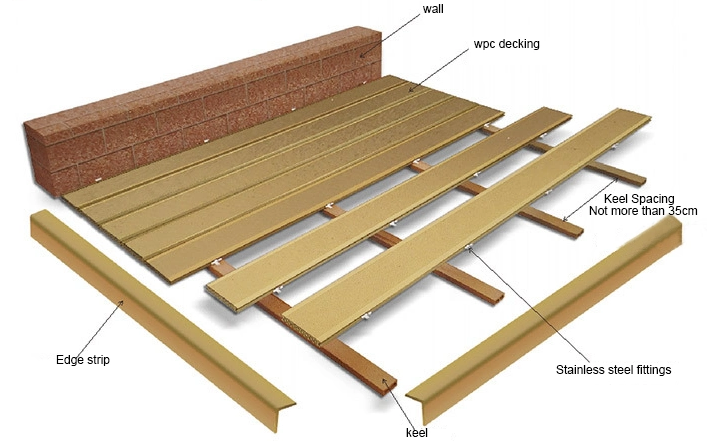

1.Prepare the ground:

Make sure the ground is flat, dry and free of debris. If the ground is uneven, foundation treatment is required and concrete can be used to level it.

2. Laying the keel:

According to the length of the floor board, determine the distance between the keels, usually between 30-40 cm.

Use an electric drill and screws to secure the keels to the ground, making sure they are parallel and firm.

3. Install the first floor:

Place the first piece of wood plastic hollow flooring on the keel and fix one end with an electric drill and screws.

Make sure the first floor is perpendicular to the joists and use a spirit level to check for smoothness.

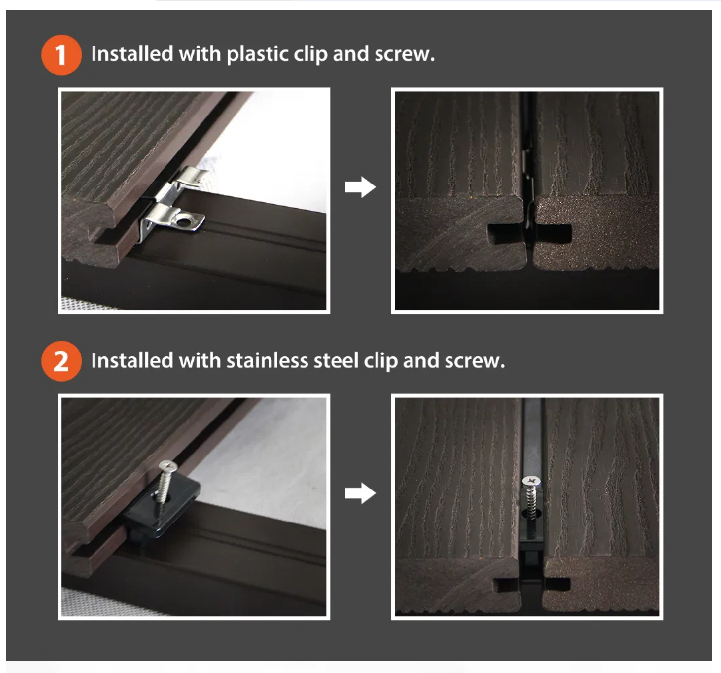

4. Fixed floor:

If using snap-on installation: Insert the snap into the groove on the side of the floor, and then fix the snap onto the keel with screws. Next, place the next piece of flooring so that it snaps into the clips.

If fastening with screws: Drill holes in the edges of the floor and use screws to secure the floor to the studs. Be careful not to overtighten to prevent damage to the floor.

5.Continue installation:

Repeat the above steps to install the wood-plastic hollow flooring piece by piece. After every few floors are installed, use a spirit level to check that the floor remains level.

6. Cut edge flooring:

When you encounter edges or obstacles, you need to cut the flooring with a chainsaw or hand saw according to the actual size to fit the space.

7. Complete the finishing:

The final piece of flooring may need to be cut and adjusted to make sure it fits snugly. Secure the last piece of flooring with screws.

Install floor edge trim or batten to increase appearance and stability.

Hot Tags: wood plastic composite hollow decking, China wood plastic composite hollow decking manufacturers, suppliers, Residential WPC Louvers, Co extrusion WPC Wall Panel, Outdoor Garden Composite Fence, Home WaterProof Ceiling Wall Panel, Light Steel Frame Houses, Lightweight Steel Frame Construction