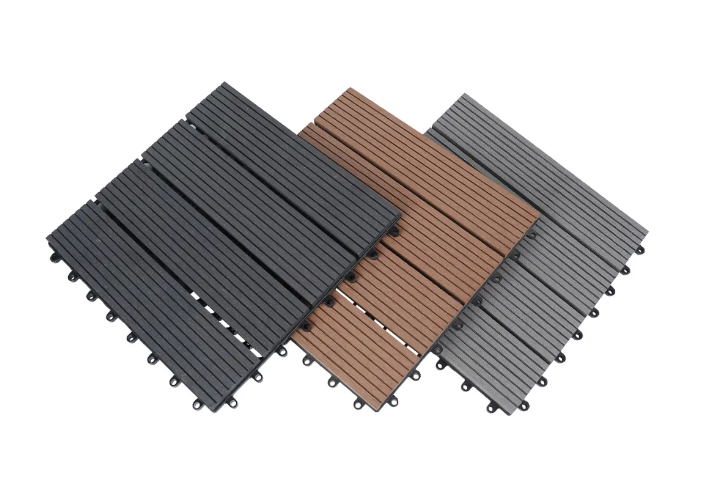

Products Description

| Material composition | Wood+ HDPE+ Additives |

| Product profiles | Hollow (square/ round holes structure) or solid |

| Surface treatments | Sanding, Embossing, Brushing, Smooth |

| Product finishes | Online embossed/ Co-extruded/ Classic |

| Size | 300x300mm |

| Popular colors | Havan,Brown ,Teak, Grey, Coffee,Off white,Charcoal, red wood or customized |

| Approximate loading qty | 12,000 pcs/ 1x20ft container |

| Applications | Commercial or personal, home and garden, Landscaping |

| Adavtanges over timber | Long life span, eco friendly, recyclable,easy installation |

Composite wood floor tiles are made of plastic (HDPE) and wood fibers with additives. Through specific formulas, we manufacture high-density composite wood with better strength, stiffness, and water absorption properties. The production process is basically raw material mixing granulation extrusion surface treatment cutting packaging.

WPC interlocking decking Features

1. Natural wood looking and feeling

2. 100% recyclable and eco-friendly

3. UV resistant and color stability

4. Weather resistant, suitable from -40 °C to 60 °C

5. Water-proof and erosion-proof

6. No insect and moldy-proof

7. No cracking, warping and splitting

8. No painting, low maintenance , easy instal and clean

9. High density , durable and firm for long lifetime

Top 10 advantages of wood-plastic composite(WPC) material.

1. Novelty. Compared with natural wood and traditional wood composite materials, it is a more novel, natural, and aesthetically pleasing new type of building material.

2. Low loss. Wood plastic can be customized according to customer needs, while natural wood is mostly fixed and needs to be cut by customers, causing losses.

3. Save. For example, when installing outdoor flooring, natural wood may need a thickness of 45mm, but in the case of wood-plastic, the corrosion resistance of 25mm thickness is better than 45mm, so the use of materials is more economical.

4. High quality. When WPC is used in large-scale outdoor installation, it can be waterproof and moisture-proof, and is not easy to crack and rot.

5. Environmental. Wood-plastic products do not need to be painted on the surface, so they do not contain formaldehyde, do not contain benzene, and have the characteristics of absorbing syllable energy.

6. Keep it small. Wood generally needs to be maintained or painted within 1 year. In the long run, the maintenance cost of wood plastic is much lower than that of wood products, and it saves materials such as paint and labor costs.

7. Long life. Testing data from foreign authorities show that the service life of wood plastics is far more than 10 years, up to 50 years, and the service cycle is long.

8. Stability. Wood-plastic products have the characteristics of anti-aging, anti-mildew, anti-corrosion, anti-moth, effective flame retardant, weather resistance, etc., can be used in the outdoor climate change environment for a long time.

9. Wider application. It is suitable for living room, hotel, entertainment place, bathroom, office, kitchen, toilet, school, hospital, sports ground, shopping mall, laboratory and other environment.

10. Convenience. No odor pollution after decoration, can be immediately moved in, is a real green environmental protection products. And with a buckle, easy to install and save time.

Product application

Packaging and shipping

Hot Tags: environmentally friendly outdoor wpc diy flooring, China environmentally friendly outdoor wpc diy flooring manufacturers, suppliers, Modena Pergola, Prefab Steel Container Homes, Co extrusion WPC Wall Panel, Waterproof WPC Outdoor Wall Panel, Outdoor Engineered WPC Decking, Indoor 3D WPC Wall Panel