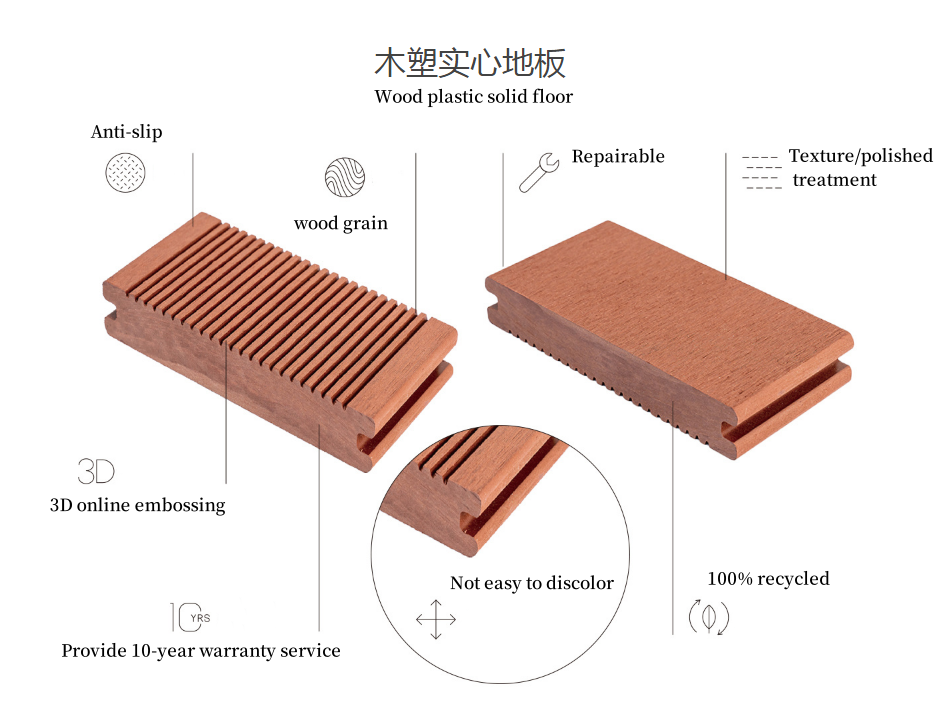

Wood plastic solid flooring is a composite flooring composed of wood fibers and plastic (usually polyethylene). It is usually made from wood fibers (such as wood chips, wood powder, etc.) and plastic particles through mixing, extrusion and other processes. Wood-plastic solid flooring has an appearance and texture similar to wood flooring, but also has the advantages of plastic flooring, such as water resistance and corrosion resistance. Compared with traditional wooden floors, wood plastic solid floors are more environmentally friendly, durable, and easier to clean and maintain. It has a wide range of applications in indoor and outdoor flooring, such as home floors, public places, terraces, gardens, etc.

Features:

It is easy to install and can be nailed, drilled, cut, and bonded.

It has good stability, does not crack or deform, and requires no maintenance.

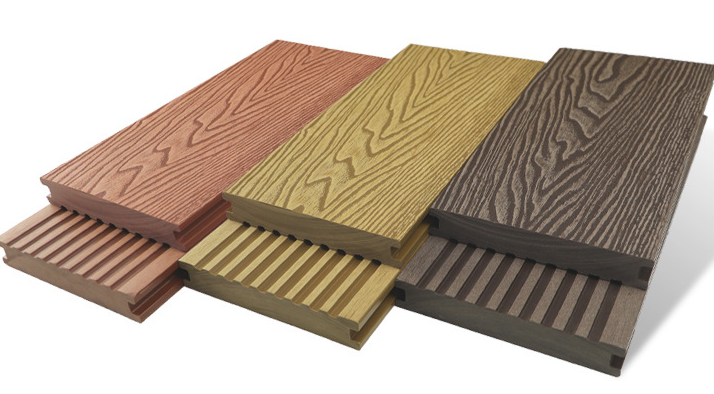

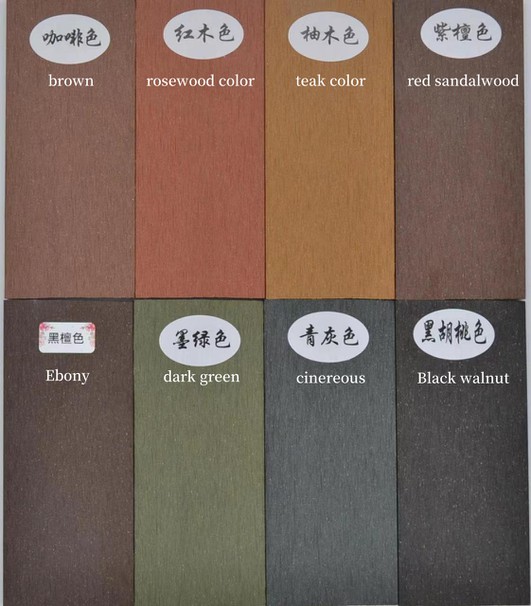

It has product diversity, various specifications and sizes, and rich colors, which can meet the various choices of customers.

It has excellent properties such as waterproof, anti-corrosion, anti-aging, no insect infestation, no fungus growth, acid and alkali resistance, no toxicity, no pollution, etc.

It has the characteristics of high strength and strong plasticity, and is suitable for various indoor and outdoor places.

It is healthy and environmentally friendly, non-polluting and non-toxic, and can be 100% recycled and reused.

Can choose colour:

Product advantages

Environmentally friendly and healthy, zero formaldehyde

Made of natural wood powder + resin extruded at high temperature, its formaldehyde emission is extremely low, giving you more peace of mind.

Paint-free, waterproof and more durable

It adopts a polymer anti-corrosion organic formula, which can effectively solve the problem of wood's fear of water and rot, and can cope with various extreme environments without the need for painting.

Strong flame retardant properties

Wood fibers are often mixed with plastics to form a uniform composite material, which reduces the overall combustion performance. We add chemicals such as flame retardants to the raw materials to improve their flame retardant properties and make them safer and more reliable.

Insect repellent properties

The cellulose fibers in wood-plastic solid flooring are usually processed, such as heating, compression and other processes, to make the surface of the cellulose fibers smooth and delicate, making them less susceptible to moth damage.

Wood plastic solid flooring, main application directions: outdoor plastic wood flooring, plastic wood exterior wall panels, plastic wood guardrails, plastic wood fences, plastic wood pavilions, plastic wood gallery frames, plastic wood flower boxes, plastic wood leisure chairs, garden benches, etc. wait.

Overall, wood-plastic solid flooring has good performance and wide application prospects, and is gradually recognized and favored in the flooring industry.

Although wood-plastic flooring can ensure wear resistance and long-term use, special attention must be paid to its preservation. Avoid collisions and other problems, and handle them properly during the installation process to avoid affecting the later use of the floor.

The company's main products include: plastic wood flooring, plastic wood fence/fence/railing, plastic wood pavilion flower stand, plastic wood wall panels, plastic wood interior materials, plastic wood art landscape, bamboo wood flooring, bamboo wood interior and exterior decorative wall panels, Light steel structure houses, light steel keel prefabricated houses, urban park houses, post stations, rural energy-saving houses, public toilets, containers, etc.

Hot Tags: solid floor, China solid floor manufacturers, suppliers, Prefabricated Light Gauge Steel Building, WPC Floor Panel, WPC Decorative Ceiling Panel, Prefabricated Modular Commercial Buildings, Modern Prefab Commercial Buildings, Co Extrusion WPC Decorative Wall Panel