Products Description

| Width | 155mm |

| Thickness | 20mm |

| Length | 2.2m,2.9m,3.6m,5.8m or Customized |

| Color | Original wood yellow, redwood, teak, brown, gray, black. |

| Surface | Smooth,Brushed,Wood Grain&sanded optional |

| Component | HDPE+Bamboo Fibers+Chemical Additives |

| Applications | Outdoor wall decoration |

|

Features |

Beautiful and elegant nature wood grain texture and touch UV & fade resistance, high density, durable use Good weather ability, suitable from -40ºC to +60ºC Can be shaved, nailed,drilled and cut to fit different specifications. Easy to install & low labor cost No paintinf, no glue, low maintenance Environmental friendly, fully recyclable and no other hazard chemical, saving forest resources |

Installation Notes

1.Preparation:

Material and tool preparation: Make sure all hanging boards, fixings, sealing materials and tools (such as electric drills, levels, cutting tools, etc.) are available.

On-site measurement and marking: Measure the wall according to the drawings, and mark the installation location and fixing points of the hanging boards on the wall.

2.Basic processing:

Wall cleaning: Remove dust, oil and other debris on the wall to ensure the surface is dry and smooth.

Waterproofing: If necessary, waterproof the wall to prevent water seepage later.

3.Install keel (if required):

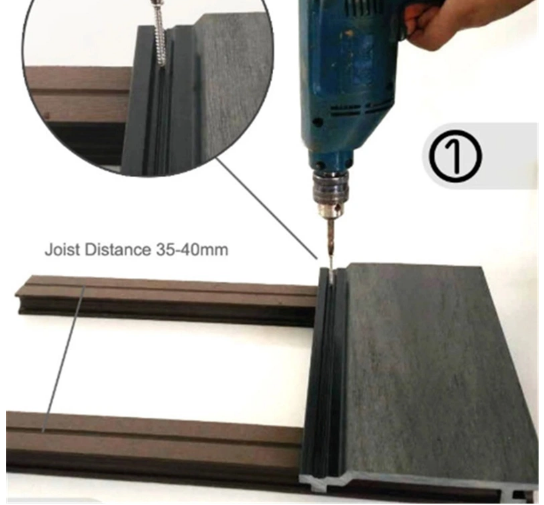

Install horizontal and vertical keels: According to the design requirements, install the horizontal keels first and then the vertical keels. Make sure that the distance between keels meets the specifications of the hanging board and that the keels are firmly fixed.

Check the flatness of the keel: Use a horizontal ruler and a vertical ruler to check the flatness and verticality of the keel, and make adjustments if necessary.

4. Install hanging board:

Installation from bottom to top: usually start installing hanging boards from the bottom of the wall and install them layer by layer upward. This ensures that the weight of each layer of siding is supported by the siding below.

Fix the hanging plate: Align the hanging plate with the keel, and use self-tapping screws or other fixings to fix the hanging plate on the keel. Pay attention to the spacing and position of the screws to ensure the firmness and aesthetics of the hanging board.

Seam treatment: The seams between hanging boards must be properly treated and can be sealed with sealant or other waterproof materials to prevent rainwater from penetrating.

5. Handling details:

Edge treatment: The installation of hanging boards at corners, windows, door frames, etc. requires special attention. Special edge strips or decorative pieces can be used.

Cut and adjust: Cut and adjust the siding as necessary to ensure the size and shape meet actual needs.

6. Inspection and Repair:

Overall inspection: After the installation is completed, comprehensively inspect the installation quality of the hanging panels to ensure that the flatness, verticality and joint processing meet the requirements.

Repair and clean-up: Repair problem areas and clean up the construction site to ensure that the exterior walls are clean and beautiful.

Applications:

1. Landscape works: outdoor decking, garden pavilion, fence, fences, handrails, doors, windows, home decor

2. public facilities: flower boxes, waste bins, lampposts, bus station, road isolation facilities, highway noise barriers

3. Entertainment facilities: style, ceilings, tables and chairs

4. Decorative facilities: floor, wall decoration panels, interior panels, wall panels, stairs board

5. Logistics facilities: tray, pad warehouse, packaging equipment

Packaging and shipping

Hot Tags: modern wpc outdoor decorative wall panels, China modern wpc outdoor decorative wall panels manufacturers, suppliers, Pergola, Waterproof Outdoor WPC Fence, Modern Art WPC Louver, Core Floor WPC Waterproof Flooring, Prefabricated Light Gauge Steel Building, WPC Fencing Panels