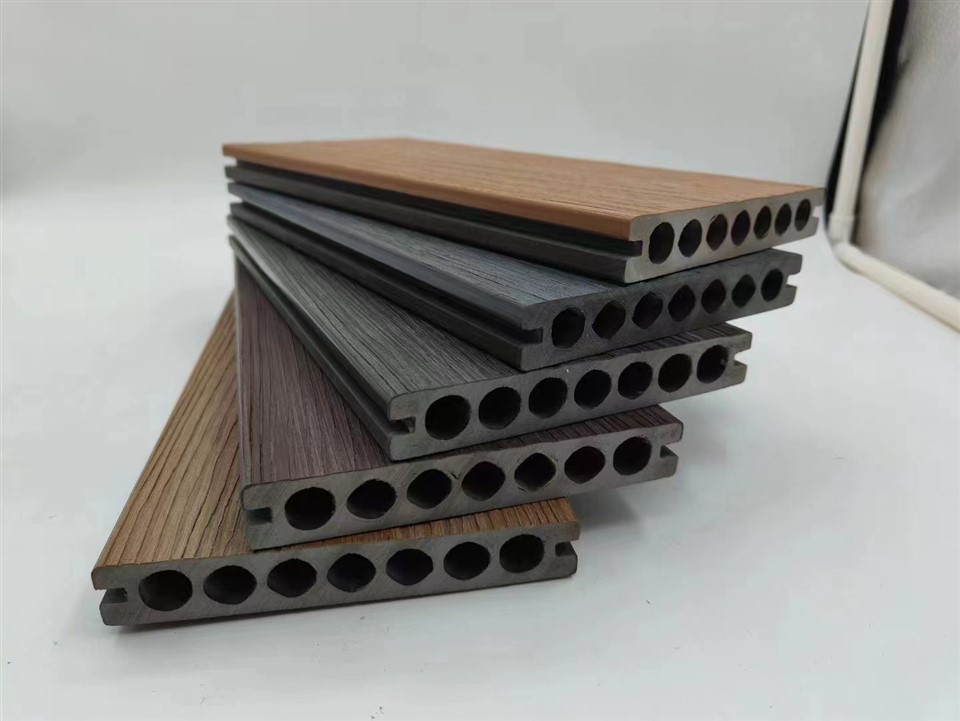

Products Description

| Product Name | ASA WPC Co-Extruded Decking |

| Material | ASA, Wood Fiber , Additives |

| Size | 140x25mm |

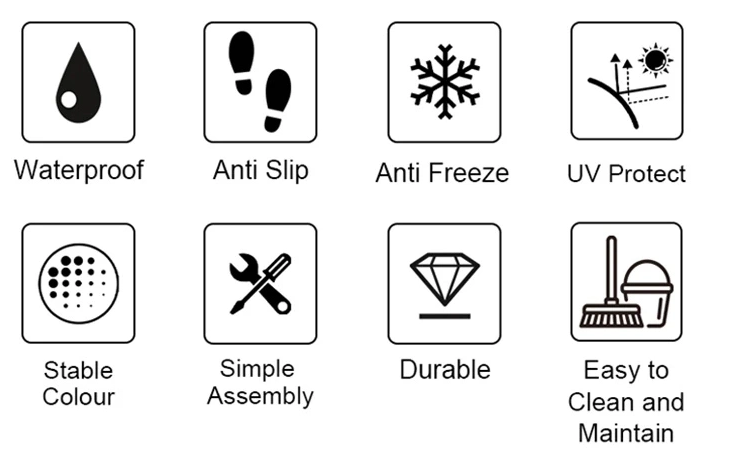

| Features | Waterproof, Anti-Static, Thermal Insulation, Fireproof |

| Surface treatment | Sanding/ Embossing/ Brushing |

| Package | Bulk or Carton Package |

| Scene | Widely used in household,garden , swimming pool , open-air-restaurant, marina |

| Installation | Fixed installation with keel fittings |

Product advantages

Its advanced material composition and manufacturing process contribute to a longer service life.

1. anti-corrosion, anti-bacterial, anti-aging.

2. easy to clean,heat insulation and sound insulation.

3. Vivid surface patterns, which looks more elegant and style.

4. Good maintainability.

clinching, planing, sawing, drilling and painting are all available.

5. Easy to install, maintenance, and clean.

6. Free of maintenance.

No cracking, swelling and deforming; Free maintenance and keeping, easy cleaning; cost saving for the maintenance and keeping.

7. Various colors and patters provided, which can meet all the requirements of different customers.

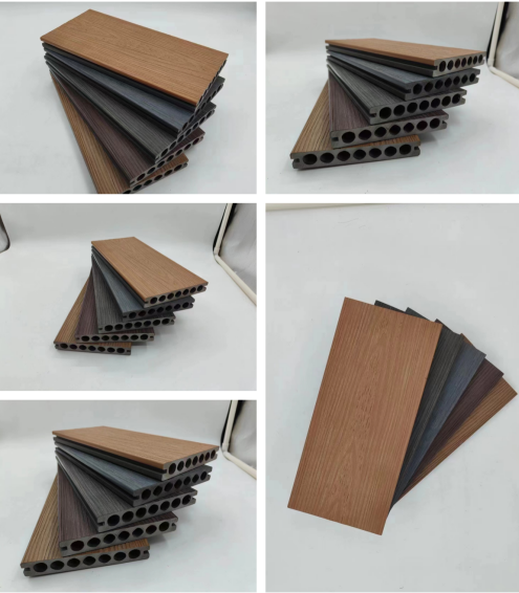

Product display

1, excellent color fastness

2, good surface hardness

3, easy for cleaning and free maintenance

4, more protection due to the outmost co-extrusion layer.

5, eco materials and can be recycled.

6, natural appearance

7, insect resistance

8, already popular in USA for years

product details

Product installation

Install keel:

According to the layout plan of the floor, keels are laid on the ground. Usually the keel spacing is 30-40 cm.

Use a spirit level to check whether the keel is level. If it is not level, you can place thin sheets in the low areas to make adjustments.

Fix the keel to the ground with expansion bolts or screws.

Laying waterproofing layer (optional):

Lay a waterproof membrane on the keel to prevent ground moisture from affecting the floor.

Laying wood plastic flooring:

Start laying the first piece of wood plastic flooring from one side, ensuring that it maintains a 5-10 mm expansion joint with the wall.

Use an electric drill and screws to fix the wood-plastic flooring to the keel. Pay attention to the spacing of the screws. Usually 2-3 screws are fixed for each floor.

When laying the next floor, be sure to leave expansion joints and ensure a tight connection between floors.

Repeat the above steps to lay the remaining wood plastic flooring in sequence.

Edge processing:

The final floor to be laid needs to be cut according to the actual size, and expansion joints must be reserved.

Use edge strips or skirting to treat the edges of the floor to make it more aesthetically pleasing.

Applications

Packaging and shipping

Company Profile

Wood plastic products Our company produces and exports wood-plastic composite panels, WPC fence panels, WPC flooring, WPC indoor and outdoor wall panels, sound-absorbing and sound-insulating wall panels, etc.

Factory production line Our factory has more than 10 production lines. Our mission is to pay attention to the issues that our customers care about and continue to create the greatest value for our customers.

Team Advantage We have a motivated and enthusiastic team with expertise in the field. Follow us. We will be your best supplier.

Hot Tags: asa wpc co-extruded decking, China asa wpc co-extruded decking manufacturers, suppliers, Prefabricated Building, Prefabricated Light Steel Frame House, Solid WPC Floor, WPC Wall Louvers, Prefab A Frame Kit Homes, Prefab Modern A Frame House