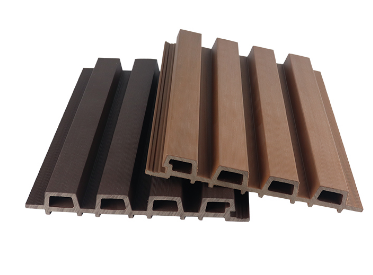

Wood-plastic composite exterior wall panel is a new type of exterior wall decoration material, usually composed of wood fiber, plastic and other additives. This composite material has the texture of wood and the weather resistance of plastic. It is waterproof, anti-corrosion, weather-resistant, and UV-resistant. It is easy to install and has low maintenance costs. Wood-plastic composite exterior wall panels are becoming more and more popular in exterior wall decoration and are widely used in exterior wall decoration of residences, villas, public buildings, etc.

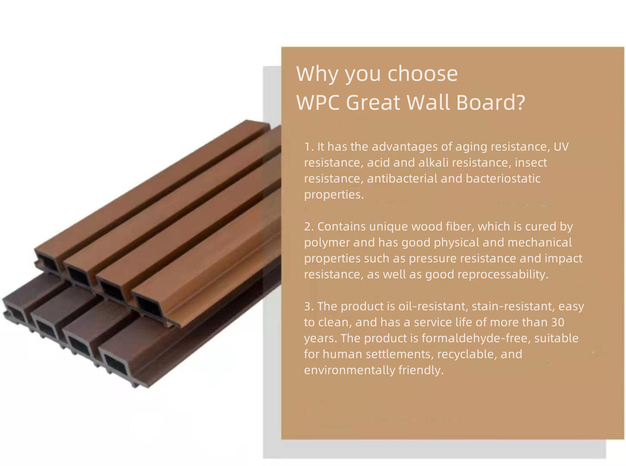

The service life of outdoor wood-plastic panels is affected by multiple factors, including material, usage environment, usage conditions, installation quality, etc. Generally speaking, with suitable materials and usage conditions, the service life of outdoor wood-plastic panels can reach about 15-30 years. If the material is poor or the installation quality is poor, the service life will be greatly shortened.

How to extend the service life of wood plastic panels?

Use high-quality wood-plastic board materials. High-quality wood-plastic board materials are waterproof, anti-corrosion, anti-aging and other properties, which can effectively extend the service life. Therefore, when choosing wood-plastic panels, choose a manufacturer with good reputation and high quality.

Keep WPC dry. Moisture is the enemy of WPC and can easily lead to rot and deformation of WPC. Therefore, keep WPC panels as dry as possible and avoid prolonged contact with water and wet soil.

Maintain wood-plastic panels regularly. During use, wood-plastic panels must be cleaned and maintained regularly, such as regular brushing and anti-corrosion paint application, to maintain their appearance and service life.

The installation quality should be good. During installation, installation must be carried out strictly in accordance with the instructions to ensure that the fixings and connections are firm and reliable.

In short, the length of service life is related to multiple factors such as material and usage conditions. If you choose high-quality materials, keep them dry and perform regular maintenance and standard installation, you can extend the service life of the wood-plastic panels and avoid quality problems.

Material properties

The product has the same processing properties as logs. It can be nailed, drilled, cut, bonded, and connected and fixed with nails or bolts. The surface is smooth and delicate, and does not require sanding or painting. The paint has good adhesion and can also be painted according to personal preferences. paint.

The product has better physical properties than logs, better dimensional stability than wood, and will not produce cracks, warping, wood knots, or twill. Adding colorant, coating or composite surface layer can make a variety of colorful products, so regular maintenance is not required.

A variety of specifications, sizes, shapes, thicknesses and other requirements, which also include providing finished products with a variety of designs, colors and wood grains, giving customers more choices.

The product has excellent properties such as fireproof, waterproof, corrosion-resistant, moisture-resistant, not insect-eaten, fungus-free, acid-alkali-resistant, non-toxic, non-polluting, etc., and has low maintenance costs.

The product has a wood-like appearance, is harder than plastic, has a longer lifespan, can be thermoformed, has high strength and saves energy.

The product is solid, lightweight, thermally insulating, has a smooth surface, does not contain formaldehyde and other harmful substances, and is non-toxic and pollution-free.

Hot Tags: exterior wpc cladding, China exterior wpc cladding manufacturers, suppliers, Prefabricated Container Building, WPC Interior Louvers, WPC Deck Flooring, WPC Louvers, Corridor WPC Ceiling Panel, Prefab A Frame House